Steel Construction

STEEL CONSTRUCTION

Stahl bietet viele Vorteile. Er hat im Vergleich zu anderen Werkstoffen eine vergleichsweise kurze Planungs- und Bauzeit und ist leicht zu verarbeiten.

We are certified according to DIN EN 1090-1 EXC3 and DIN EN ISO 3834-2 in the area of steel construction. Our machinery is state of the art. With our double miter saw, we can cut pipes and sectional steel up to a diameter of 500 mm or 500 mm edge length.

Our welding equipment is calibrated annually and is state of the art. MAG welding is possible up to 500 amps and TIG welding up to 300 amps. The welders all have valid qualifications. All steel parts for welding are cleaned of scale, rust etc. in our in-house sandblasting facility.

The various components are welded together on modern welding tables with extraction. Components weighing up to 15 tons are no problem for us.

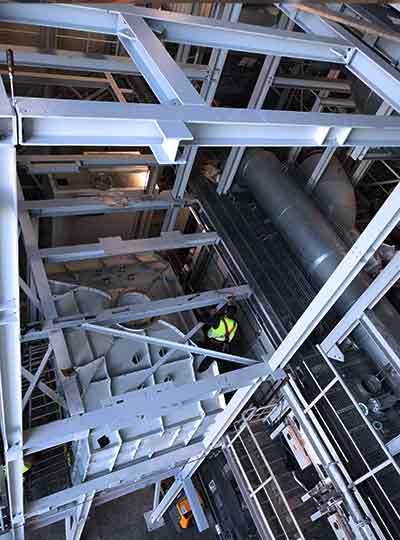

We also undertake the planning and construction of the desired steel components according to customer requirements. Assembly is carried out by our highly trained assembly team.

We can provide an in-house level 2 NDT inspector for weld seam inspections. The following NDT inspections are possible: dye penetrant testing (PT), magnetic particle testing (MT) and visual testing (VT).

The company manufactures steel components such as steel platforms, steel halls, machine base frames, stairs and railings, as well as all components to customer specifications. These also include steel parts for the offshore sector.